A while ago I used some resin embellishments I had lying around to make knee walls for the Victorianna’s nursery. The one to the left of the tower door would have looked like this.

Since then, I finished the master bathroom, which is next to this room. In the bathroom I put a piece of siding under the sloped part of the roof. To be consistent I decided to do the same in the nursery (and I’ll also do it in the master bedroom, on the other side of the house).

I built a shelf to attach the siding to.

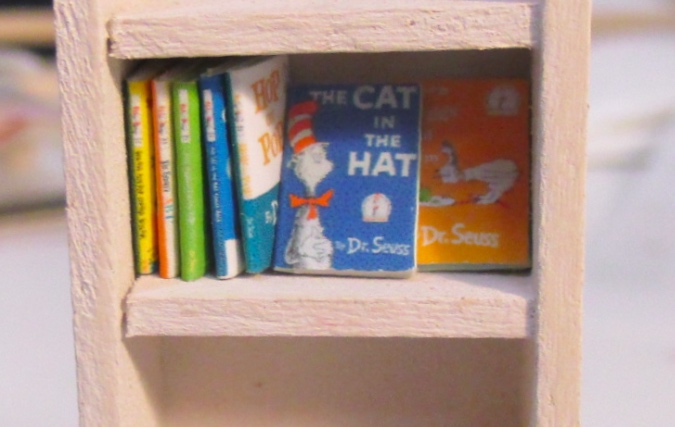

My initial plan was to fill the shelf with books. Here are some I made with covers I found online and resized.

But I would have had to make a lot of books to fill up those shelves, plus the covers aren’t visible once they’re on the shelf, especially from the angle where this shelf will be installed.

The nursery already has a toy shelf in the corner and I didn’t think it needed another one, so I ended up making baskets. I made these the same way I did the linen closet basket, except I didn’t bother with piping. The material is “fiddler’s cloth” that I had in my cross stitch stash (a thrift store purchase). I don’t know why it’s called fiddler’s cloth, it just looks like Aida to me.

Before I could glue in the shelves and siding, I needed to figure out what to do about trim around the tower door. This has stumped me for a while. The gaps between the roof cutout and tower walls would have required large pieces of trim to cover up, and I just couldn’t think of a classy way to do it.

I stared at this for a very long time and kept thinking, “If only I could redo the ceiling!” Well, why not?

I made a ceiling template using strips of paper. Here are the first two pieces. To figure out the angle, I just put the piece of paper in place and folded it where it met the wall, then cut along the fold line.

I worked my way across the ceiling, taping the strips together as I went.

Here’s the finished template. It doesn’t look tight against the tower in this picture (and the next one) because it’s held on loosely with tape, but in reality it’s a snug fit.

Next I traced the template onto a piece of stiff paper.

I glued that to a piece of ceiling paper larger than the template.

Then I cut around the edges with an Xacto knife.

I neglected to take a picture of the new ceiling before I started adding trim, which is a shame, because it looked beautiful. The seams against the tower are nice and tight and you can’t tell at all that it’s glued on top of the original ceiling.

Continue reading

Emily is a freelance writer, miniaturist, and adventure game enthusiast.

Emily is a freelance writer, miniaturist, and adventure game enthusiast.